Aircraft Structural Health Monitoring - Open Access Policy Institutional Open Access Program Special Topic Guidelines Editorial Process Research and Publication Ethics Article Processing Fee Awards Feedback

All articles published in are immediately available worldwide under an open access license. No special permission is required to reuse all or part of a published article, including figures and tables. For articles published under the Creative Commons CC BY open access license, any part of the article may be reused without permission, provided the original article is clearly cited. For more information, see https:///openaccess.

Aircraft Structural Health Monitoring

Presentation papers represent cutting-edge research with significant potential for significant impact in the field. Articles are sent by invitation or individual recommendation of scientific editors and are reviewed before publication.

Sensors May Monitor Aircraft For Defects Continuously

A submitted paper may be an original research paper, a significant ground-breaking study, often involving multiple methods or approaches, or a comprehensive review paper with concise and accurate updates of recent developments in the field that systematically reviews the most interesting advances in the literature This type of work offers insight into future directions research or possible applications.

Editor's Choice articles are based on the recommendations of scientific journal editors from around the world. The editors select a small number of articles recently published in the journal that they believe will be of particular interest to readers or important in the relevant field of research. The aim is to offer a brief overview of some of the most interesting work published in the various research areas of the journal.

Structural Integrity and Composites Group, Faculty of Aerospace Engineering, Delft University of Technology, Kluyverweg 1, 2629HS Delft, The Netherlands

Center of Excellence for Artificial Intelligence for Structures, Faculty of Aerospace Engineering, Delft University of Technology, Kluyverweg 1, 2629HS Delft, The Netherlands

Cessna Set To Deliver Upgraded Citation X In Q2, Learjet 85 Prototype Flying With Structural Health Monitoring System

Received: 8 February 2022 / Revised: 18 March 2022 / Accepted: 23 March 2022 / Published: 30 March 2022

With the increased use of composites in aircraft, many new successful contributions have been made to the field of structural condition monitoring (SHM) for composite aerospace structures. However, its application is still uncommon in the operational environment of the aviation industry, mainly due to the gap between the research approach and application, which limits the transition to advanced aircraft maintenance strategies such as condition-based maintenance (CBM). In this paper, we identify and highlight two key aspects involved in the development of the SHM field for aircraft composite structures: (1) the aircraft maintenance engineer requires comprehensive damage assessment to manage the health of the aircraft structure, and (2) scaling up. application of SHM to realistic composite structures of aircraft in operational conditions. Multisensory data fusion concepts can help address these aspects, and we articulate their benefits, opportunities, and challenges. Additionally, for demonstration purposes, we show a conceptual study of a fusion-based SHM system for multi-level damage monitoring of a representative aircraft wing composite structure. Below, we present how multi-sensor data fusion concepts can be useful to the community in advancing the field of SHM for aircraft composite structures to operational CBM applications in the aerospace industry.

The use of composite structures in the aerospace industry has increased over the past few decades, with new aircraft such as the Airbus A350 or the Boeing 787 made primarily (53% [1] and 50% [2] respectively) of composite material. This development can be attributed to its mechanical properties, which include a high strength-to-weight ratio and corrosion resistance. Therefore, the use of composite structures in aviation technology can lead to a decrease in operating costs due to lower fuel consumption and fewer maintenance works [3]. Although many advantages can be recovered with composite aircraft structures, their behavior also poses a problem; in particular, the inspection and tracking of damage to the aircraft structure becomes more difficult because the damage may be present internally but cannot be identified by visual inspection of the outer layers of the aircraft structure during maintenance procedures. In addition, even if signs of damage are visible on the surface, for example, in the form of barely noticeable impact damage, their size may not reflect the actual extent of damage to the internal layers of the composite [4, 5, 6, 7]. ]. In addition, damage mechanisms and growth behavior are complex, making it difficult to predict damage growth in composite aircraft structures under load.

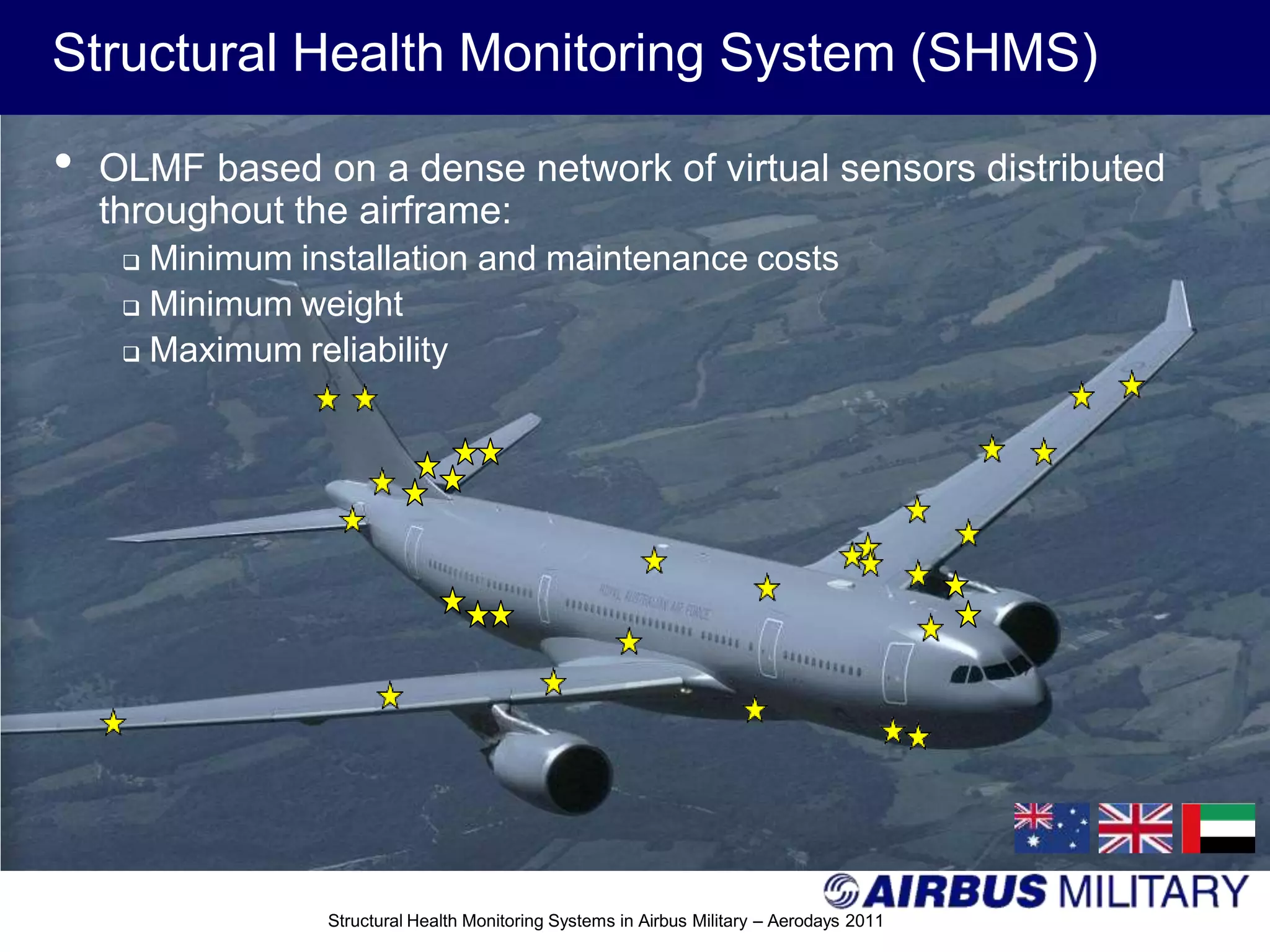

In the aviation industry, these unknowns must be controlled and damage detected before they compromise the structural integrity of a composite aircraft component, usually achieved by establishing predetermined inspection intervals as part of an "aircraft maintenance strategy". In addition, structural parts may be over-engineered, adding weight to the aircraft, or may be preemptively replaced during maintenance after a specified time interval. These fixed interval programs and preventive maintenance in the aircraft industry can lead to unscheduled maintenance work, extensive inspections when there is no damage, or unnecessary replacement of undamaged parts. To mitigate these aspects, a condition-based maintenance (CBM) strategy can be implemented, which can provide both economic and time benefits with an estimated benefit of more than €700 million per year for the European aviation industry alone [8]. In the CBM approach, maintenance decisions are made based on the actual state of health of the aircraft structure: maintenance actions are taken only if the structure requires repair or replacement. Therefore, this requires an indication of the structural health of the aircraft. Thus, CBM in the aviation industry for structural applications is based on structural health monitoring (SHM) techniques, which consider permanently installed sensor networks to collect data for health management consisting of damage detection and control. Thus, sensor data is used to assess the presence of damage to the structural part of the aircraft, predict the future growth of damage and make a decision on additional maintenance actions for this aircraft.

An Overview Of Structural Health Monitoring: From Hard Time To Online Monitoring

The application of SHM in the aerospace industry has not yet fully matured [9], and especially its application to composite structures is a challenging task. For a realistic aircraft maintenance scenario, the needs of the maintenance engineer in the end application must be considered: What health management information is needed to make additional decisions about aircraft maintenance? For example, as we will discuss in this paper, this requires comprehensive damage diagnosis at all four levels of SHM instead of a single level, namely: (1) damage detection, (2) damage localization, (3) damage type identification, and (4) severity damage For aircraft maintenance, the next step beyond damage diagnosis should also be included, which is damage prediction, in which the remaining service life (RUL) of the aircraft structure is determined based on collected sensor data. That is, an aircraft maintenance engineer needs to know whether there is damage in a given aircraft, as well as its characteristics and the future effect on the characteristics of the entire aircraft. In addition, in the operational scenario, large complex aircraft structures will be operated under realistic load conditions, requiring robust, probabilistic and scalable algorithms. The requirements and intended functions of the SHM system for the aviation industry have been compiled and discussed in detail in the SAE standard ARP6461 [10].

In this paper, we will dive deeper into the challenges of controlling complex composite aircraft structures using SHM. We argue that a multi-sensor data fusion approach is necessary and beneficial for applications in the aerospace industry. That is, it can, among other things, lead to a more complete picture of the current damage, reduce ambiguity and increase confidence in the results [11, 12]. Although there have been studies on data fusion in the broader sense of SHM [13], there have been no studies on its application to composite structures with aerospace applications. In this work, we conceptually approach these ideas and justify the need for multi-sensor data fusion research for SHM of composite structures in aerospace applications.

This document is structured as follows. First, in Section 2 we identify the gaps that need to be addressed in order to apply SHM methodology to aircraft composite structures. We evaluate scaling concepts considering various application aspects of aircraft components and the concept of a comprehensive health management assessment consisting of diagnostics and prognostications required for maintenance programs. Then, in Section 3, the concept of multi-sensor data fusion is introduced and its capabilities, advantages and limitations are detailed. Chapter 4 reviews the application of multi-sensor data fusion techniques for SHM of aircraft composite structures by discussing new opportunities, practical aspects and considerations. In Section 5, we show the first indications of how multiple SHM methods and data fusion concepts can be combined by presenting a high-level design of a conceptual SHM system for an aircraft wing structural component consisting of multiple stiffness elements. Finally, Section 6 concludes this article and provides perspective.

In the aerospace industry, composite structures built into aircraft are at the component level. However, most research focuses on lower-level structures such as small exploratory coupons. When considering the successful application of SHM to these aircraft designs, several research gaps can be identified that need to be addressed. In this section, we discuss two main aspects that limit the current progress in its implementation in the aviation industry.

Structural Health Monitoring Allows Detection Of Damage To Aircraft Components Made Of Cfrp

Stainless steel aircraft cable, steel aircraft cable, stainless steel aircraft wire, aircraft steel tubing, steel aircraft hangers, stainless steel aircraft, steel aircraft hangar, galvanized steel aircraft cable, aircraft stainless steel lockwire, aircraft, 4130 aircraft steel, aircraft quality steel

0 Comments